Product testing

& certification

In-House Testing Lab

Bringing a helmet to market involves more than just a great design—it means meeting the strict safety standards required in your target markets. Whether you’re aiming for ANSI, EN, ASTM, NOCSAE, CPSC or others certification, the process requires precise testing, validation, and refinement.

As your manufacturing partner, we see it as our responsibility to help ensure your helmet can meet the testing requirements you need. That’s why we invest heavily in our in-house testing lab, where we can simulate and pre-test against global certification standards throughout the development process.

By doing this early, we help you minimize the risk of delays or failures when it’s time to certify your product. Once we’ve completed internal testing and the helmet meets all criteria, you can confidently submit your final sample batch to an official, accredited third-party lab in your country—such as COLTS, SGS, TÜV, or INSPEC—to obtain certification under your own brand name.

Our lab capabilities include:

- Impact attenuation testing

- Penetration resistance

- Retention system strength

- Roll-off and stability testing

- EPS density and rebound analysis

- Environmental conditioning (hot/cold/humidity)

This hands-on process not only accelerates development but also gives you confidence in your product’s safety and performance before investing in third-party certification.

Practical Applications of Our Lab:

If test results show that EPS compression

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If impact results suggest the shell needs

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If overall performance feels off

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

How We Use Our Testing Lab

to Support Product Development

Our in-house testing lab isn’t just for verifying safety—it’s a tool we actively use throughout the development process to make thoughtful, data-backed adjustments to your product.

By testing early and often, we can gather meaningful performance data—like impact response, EPS behavior, or structural deformation—and use that

to guide critical design decisions.

What Makes This Setup Different:

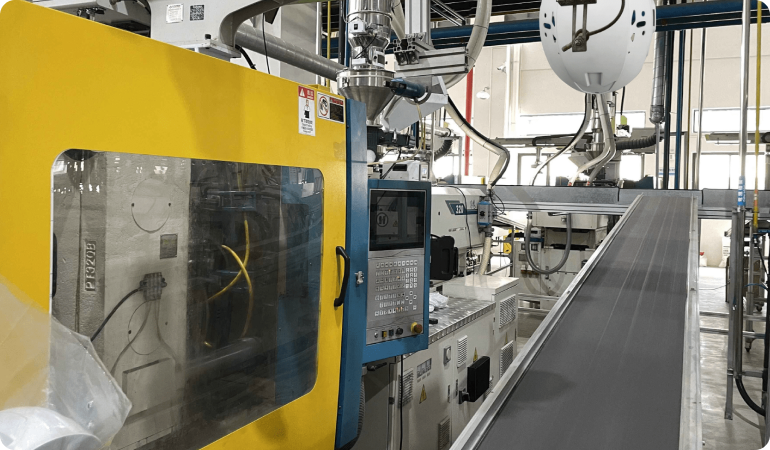

Most factories can perform tests—but they often don’t have the ability to react quickly. Changes to EPS or tooling often require third-party vendors, long lead times, and added cost.

We handle these steps internally. Because we have our own EPS molding workshop, we can:

- Adjust foam density quickly

- Produce updated samples without delay

- Immediately re-test changes in our lab

This gives us—and you—a faster, more flexible development process. It also allows us to move forward with confidence when it’s time to submit final samples to third-party labs for certification.

Let's bring your project to life!

Our team of engineers is here to help. We offer free consultations and estimates.

Fill out the form for your free cost estimate.

Our product guaranteed quality, compliance with regulations

There are more than 300 brand factories with employees and more than 50,000 square meters of factory buildings. All products are tested in accordance with product standards and testing protocols before all product development, processing, and shipment.

We focus on helmet safety with performance