EPS in mold technology

EPS Foam Tooling

the shock-absorbing core

EPS (Expanded Polystyrene) is at the heart of helmet safety, acting as the primary energy-absorbing component that helps reduce the risk of injury during impact. Every helmet we manufacture begins with this essential element—crafted in-house with high- precision aluminum molds to deliver consistent results every time.

Our EPS raw material is proudly imported from the USA, offering superior quality and reliability. This guarantees that the foam we expand, mold, and test meets the performance expectations required by global safety standards such as ANSI, EN397, and ASTM.

Applications beyond helmets:

- Protective packaging for electronics

- Children’s car seats

- Thermal containers for food and pharmaceuticals

- Seed trays for agriculture

- Lightweight drones and UAV components

EPS Working Principle – How Protection is Made

EPS starts as small closed-cell beads made of styrene and an expanding agent. During production:

- Beads are pre-expanded using steam.

- The material stabilizes, taking on a cellular foam structure.

- Beads are then molded into the helmet shape and reheated, causing them to expand further and fuse tightly together.

Our tooling ensures that this foaming process is consistent across every liner, from vent alignment to shell curvature.

In-Mold EPS Technology – Seamless Integration for Maximum Protection

Mold process

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Creates a single, unified structure

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our tooling workshop

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

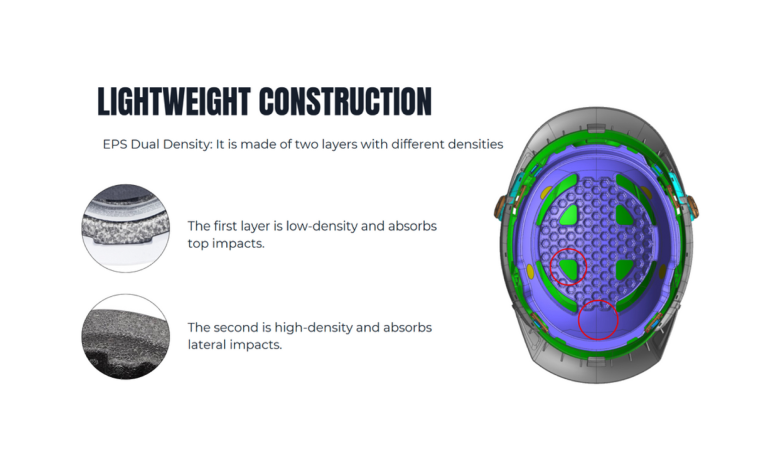

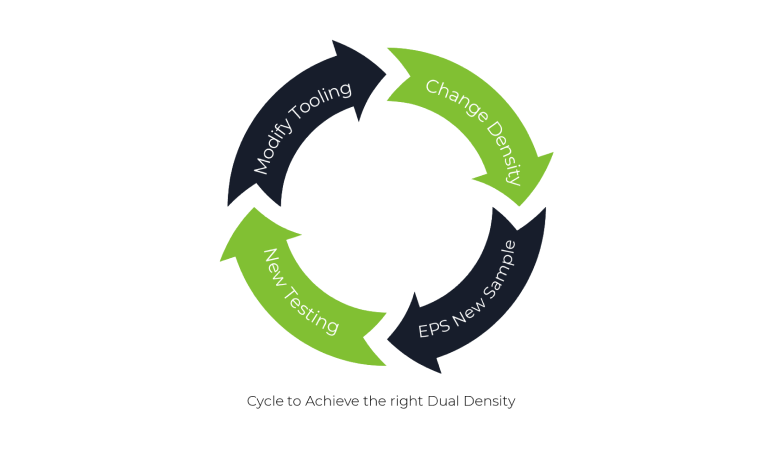

Achieving the Right Density to Pass Type II

Meeting ANSI Type II helmet standards is a highly technical process. It often takes testing 70 to 100 different EPS variations to find the right formula based on your shell structure. This is why working with a partner that owns its EPS workshop is crucial.

We manage the entire development cycle in-house:

- Change Density

- Mold New EPS Sample

- Run Impact Testing & Data Analysis

- Modify Tooling as Needed

This level of in-house capability allows us to move quickly, test thoroughly, and iterate efficiently—ensuring your helmet meets certification without delays or third-party bottlenecks.

Let's bring your project to life!

Our team of engineers is here to help. We offer free consultations and estimates.

Fill out the form for your free cost estimate.

Our product guaranteed quality, compliance with regulations

There are more than 300 brand factories with employees and more than 50,000 square meters of factory buildings. All products are tested in accordance with product standards and testing protocols before all product development, processing, and shipment.

We focus on helmet safety with performance