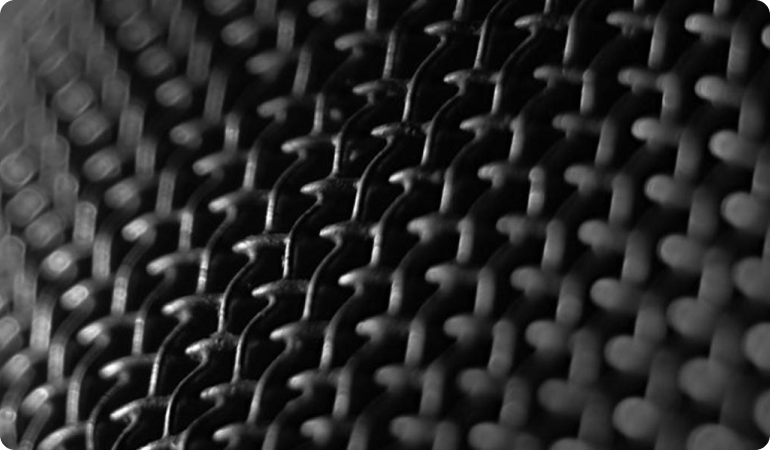

Carbon fiber custom parts

Custom Carbon Fiber Parts Capabilities

From concept to final production, our carbon fiber capabilities are built around one core principle: performance through precision.

We provide a fully integrated service—from engineering and tooling to autoclave curing and composite machining—designed to meet the demands of high-performance industries like head protection, consumer goods, automotive, defense, and sporting goods.

Design, Engineering & DFM Optimization

Every project begins with our Design for Manufacturing (DFM) approach, ensuring that your product is not only functional and innovative, but also cost-effective and scalable.

Our engineering team works closely with your team to refine the design, reduce unnecessary weight, enhance strength, and make sure the product is ready for smooth production. Whether it’s a carbon fiber helmet shell or a structural component, we tailor the design to align with your performance targets.

Autoclave & Out-of-Autoclave (OOA) Curing

We offer advanced thermoset curing options with both autoclave and OOA processing.

- Our autoclave systems provide precise control over heat, pressure, and vacuum to cure large or intricate components, ensuring excellent fiber consolidation, surface finish, and part performance.

- Out-of-autoclave (OOA) processing offers flexibility for parts that don’t require autoclave pressure—perfect for shortening lead times and reducing tooling costs while maintaining high structural quality.

This dual approach allows us to manufacture anything from high-end helmet shells to large-format structural parts without compromising integrity or consistency.

Our Carbon Fiber Capabilities

Tooling, Prototyping & Scalable Production

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Structural Bonding & Assembly

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CNC Machining

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Applications of Our Carbon Fiber Technology

Carbon fiber is one of the most adaptable and high-performance materials available today. We serve a wide range of industries and product categories, including:

- Sports & Recreation: Lightweight, protective helmets, racquets, sticks, clubs, and paddles

- Aerospace: Aircraft structural parts and assemblies with superior strength-to-weight ratios

- Automotive: Structural panels, bumper reinforcements, and ultra-light components

- Defense & Tactical Gear: Helmet shells, armor backings, and aerospace-grade component

- Medical Equipment: Radiolucent parts for imaging systems and surgical devices

- Medical Equipment: Radiolucent parts for imaging systems and surgical devices

- Consumer Products: Drones, bike frames, tech enclosures, and protective gear

Whether you need a carbon fiber helmet shell engineered for impact or a structural aerospace-

grade composite, we deliver high-performance results from start to finish—under one roof.

Let’s take your project further, faster, and stronger.

Let's bring your project to life!

Our team of engineers is here to help. We offer free consultations and estimates.

Fill out the form for your free cost estimate.

Our product guaranteed quality, compliance with regulations

There are more than 300 brand factories with employees and more than 50,000 square meters of factory buildings. All products are tested in accordance with product standards and testing protocols before all product development, processing, and shipment.

We focus on helmet safety with performance